ZST-SS-2600 SOLAR TABBER AND STRINGER MACHINE

1. Product Description

ZST-SS-2600 string soldering machine is an automatic equipment that welds the well-tested cells into strings through interconnection bars, and sorts and collects the soldered cell strings. The equipment adopts various advanced automation technologies such as PLC, SCARA robot, servo motor, infrared welding system, etc., to realize fully automatic processing from battery chip feeding to cell string discharging.

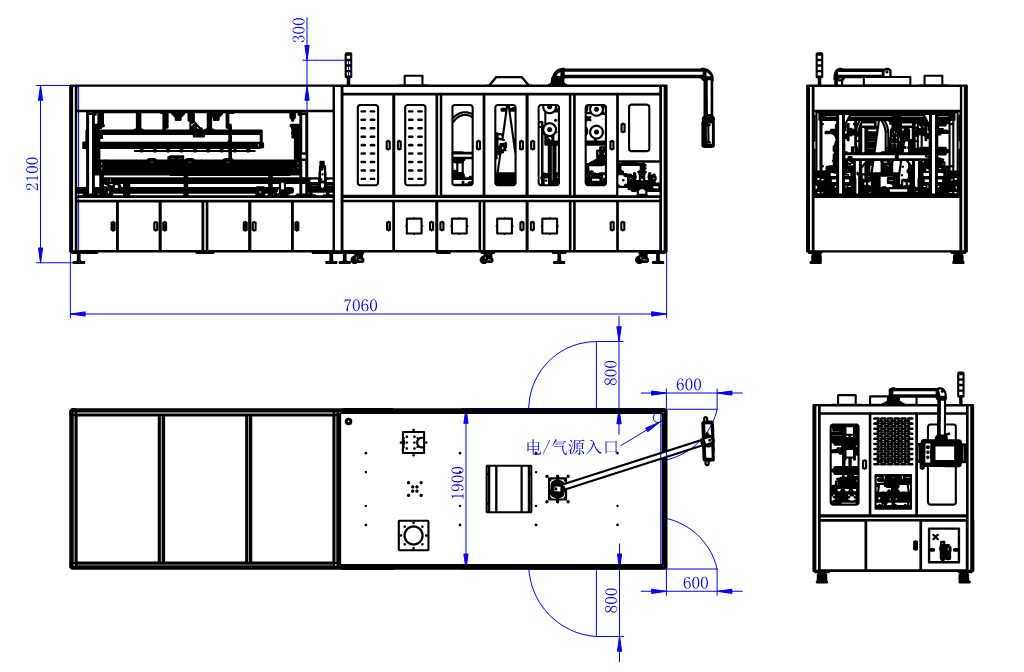

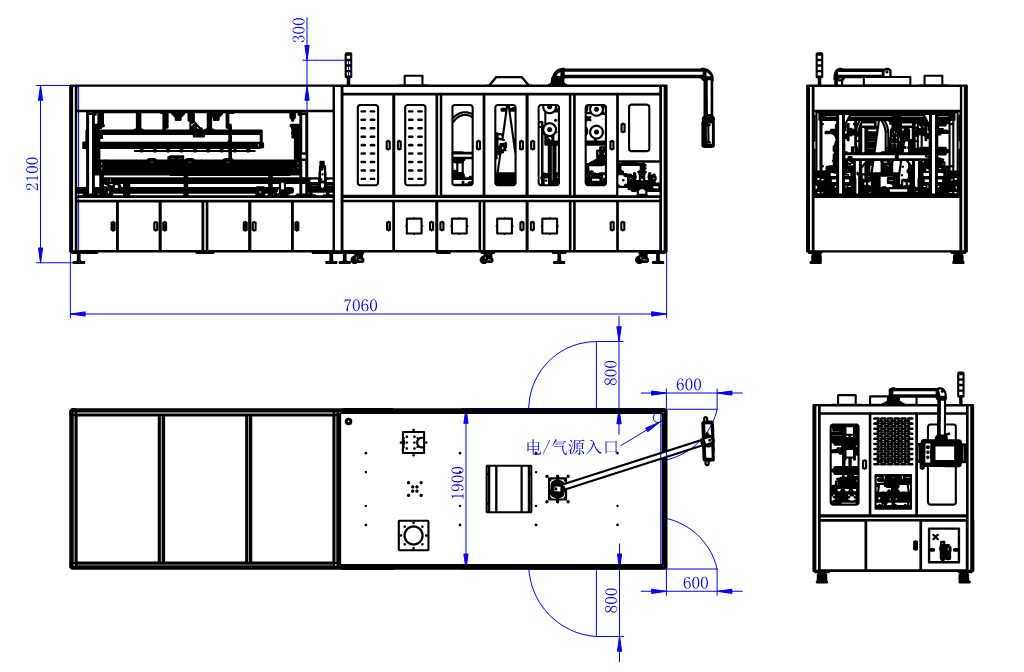

1.1Equipment outline drawing

1.2 Equipment size chart

2. Specifications

2.1 Solar cell

2.1.1 Solar cell type:156 full and 1/2 cutting cell, 158 full and 1/2 cutting cell, 166 full and 1/2 cutting cell,

182 1/2 cutting cell, 210 1/2 cutting cell and 1/3 cutting cell.

2.1.2 Solar cell thickness:160um-300um

2.1.3 Number of cell grids:5BB、6BB、9BB、MBB(Changing jigs)

Note:For each busbar you need to mount corresponding clip / slot plate / soldering ribbon processing mechanism according to the cell plate screen.

2.2 Ribbon

2.2.1 Solder ribbon type: leaded or lead-free flat ribbon

2.2.2 Soldering ribbon width: 0.6-2.0mm

2.2.3 Soldering ribbon thickness: 0.18-0.32mm

2.3 Solar Cell String

2.3.1 Maximum length: 2000mm, accuracy ± 1mm

2.3.2 Cell spacing: 0-10mm adjustable, accuracy ± 0.3mm

2.3.3 Head and tail welding tape extension length: the length can be set independently at the beginning and end, the range is 0-15mm

2.4 Soldering

2.4.1 Soldering method: infrared lamp

2.4.2 Ribbon alignment tolerance (piece): ribbon width minus busbar width

less than 0.2mm, the tolerance is less than 4%;

less than 0.2mm-0.3mm, the tolerance is less than 3%;

more than 0.3mm, the tolerance is less than 0.3%.

2.4.3 The soldering tension is not less than 1.5n × the width of the main grid line, which depends on the quality of the cell.

2.5 Operating Efficiency

2.5.1 Up time ≥ 95% (unplanned downtime of equipment / 24H), unplanned downtime refers to equipment failure or abnormal downtime.

2.5.2 Fragmentation rate ≤ 0.2% (A grade solar cell).

3. Selection of main components

Part Name | Brand |

PLC | Delta |

Servo | Delta |

Linear system | ABBA、SHAC |

pneumatic | SMC, AirTAC |

Robot | Inovance |

4. Installation requirements

4.1 Machine parameters

4.1.1 Weight:3750㎏

4.1.2 Average power:30Kw

4.1.3 Air consumption: peak 6000L / min, average 450L / min.

4.2 Site requirements

4.2.1 The installation ground load is ≥1 ton / ㎡ , the ground is flat and free of vibration.

4.2.2 Installation space (including operation) is not less thanL8000*W3900*H2300mm

4.2.3 Ambient temperature: 5-40 ℃.

4.2.4 Relative humidity: 5-70% (non-condensing).

4.3 Power requirements

4.3.1 Three-phase Five Line AC380V/ 50Hz

4.3.2 Three-phase five-wire system (L1 / L2 / L3 / N / PE). 2) Inlet specification 3*16mm²+1*12mm²+1*8mm²

4.4 Gas supply demand

4.4.1 Air pressure: 0.6-0.8MPa

4.4.2 Intake manifold uses D16mm hose

4.4.3 Compressed air quality requirements: maximum solid particles 15um (level 3), minimum pressure dew point + 3 ℃ (level 4), maximum oil mist concentration 5mg / m³ (level 4)

4.5 Exhaust requirements

Exhaust pipe diameter Φ200*2